Removing coating from very different parts made of steel, aluminium and coloured metals places high demands on mechanical engineers and chemical suppliers with regard to saving resources and efficiency. Years ago we began to address these challenges and can offer sophisticated and practice-tested concepts, which match your objectives and can be integrated into your production. Our concepts are constantly developed further, in order to meet the high demands of ecological sustainability and the requirements of modernized production processes.

Removing coating from wheel-rims – Sustainable aesthetics

Recently removing coating from wheel-rims has become a big topic. We have developed patented concepts for small businesses with manual operation, up to fully automated large-scale facilities for major factories and industrial plants. Our customers include the automotive industry and its suppliers, commercial parts cleaning services, as well as paint-shops.

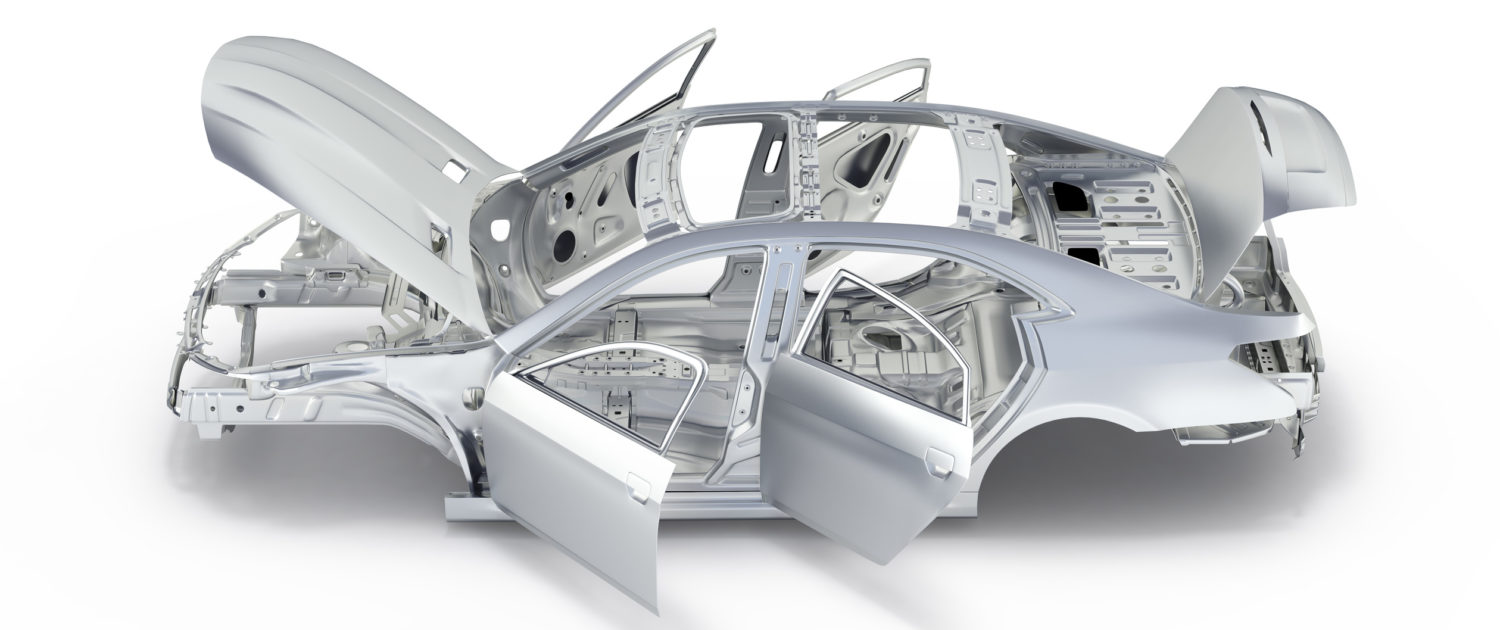

Automotive Industry -Quality combined with sustainability

We deliver dipping and spraying equipment for the removal of coating, adapted to your operating needs, specifically for the requirements of the automotive industry and its suppliers. The quality and environmental demands made by this industry are high and ever higher, creating a huge challenge for the technology of coating removal, which we gladly and successfully meet!

Removing coating from suspension gear and large Parts – Tailor-made and profitable

Coating hangers need to be stripped of coating very frequently, but also gently, in order to maximize their operating life. Thermal coating-removal methods soon meet their limits, because they negatively affect the materials and especially the surfaces of the hangers. Therefore chemical-physical coating-removal methods are applied more and more. For these tasks and for removing coating from large parts we offer you processing systems adapted to and integrated into your production. We will gladly visit you on site and work out the best solution together. You can only gain from the wealth of our experience!

Wage-contractors removing coating – Quantity with quality

A wage-contractor working in coating removal must be able to rely on close cooperation from the manufacturer of equipment and from suppliers of chemicals. In the area of chemistry we have been working closely with well-known manufacturers for over four decades and can therefore also provide you with the best recommendations in this field. Naturally our coating removal equipment for wage-contractors complies with all the legal regulations.

Removing Coating from Plastics – Difficult but solvable

A relatively new area of work, which only few providers have managed to solve satisfactorily, is coat-ing removal from plastics. This is because often the structure of the plastic is similar to the type of coating layer to be removed. In symbiosis with sophisticated and patented industrial technology (“Super Wave”) and the necessary sensitive chemicals, we can achieve excellent results removing coating without in any way damaging the plastic surface, or leaving residual coating in the drilled holes of the workpiece (“substrate”). Up to now there is no comparable quality available on the market! This is particularly interesting for the automotive industry and its suppliers, e.g. for removing coating from car parts like fuel-tank caps and bumpers.

Chemicals for removing coating – a neat solution

We work very closely with well-known and leading manufacturers of coating-removing and pre-treatment chemicals in Germany. The direct contact with our partners in application and development laboratories enables efficient cooperation with the chemical manufacturers by swift communication, in order to work out the best possible solution in the shortest time for our customers.

In all areas of coating removal we are your competent contact partner. We show you how the used chemicals can be disposed of in an environmentally friendly way, or can be utilized again in direct recycling. Test us! We welcome every challenge!

ADRESSE | ADDRESS

MSP e.K.

Maschinen- und Stahlbauservice Paegelow

Eichendorffstraße 38

53879 Euskirchen

Deutschland | Germany

KONTAKT | CONTACT

Phone: +49 2251 12 43 01

Fax: +49 2251 12 43 02

Email: j.paegelow@msp-eu.com

www.msp-eu.com